UHMWPE à¤à¤à¤

UHMWPE à¤à¤à¤ Specification

- प्रॉडक्ट टाइप

- UHMWPE Component

- प्लास्टिक का प्रकार

- प्लास्टिक मोल्डिंग प्रकार

- मोटाई

- 10 mm to 100 mm (customizable)

- स्ट्रेंथ

- High Impact Strength

- शेप

- Custom Shape (as per drawing or requirement)

- Wear Resistance

- Excellent

- Surface Finish

- Smooth

- Applications

- Material handling, conveyor systems, linings, wear strips, guide rails

- Machinability

- Excellent

- Color

- White, Black, Green, or as required

- Water Absorption

- <0.01% (at 23°C for 24 hrs)

UHMWPE à¤à¤à¤ Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- एफओबी पोर्ट

- Mumbai

- भुगतान की शर्तें

- वेस्टर्न यूनियन, चेक, कैश एडवांस (CA)

- आपूर्ति की क्षमता

- प्रति सप्ताह

- डिलीवरी का समय

- हफ़्ता

- मुख्य निर्यात बाजार

- एशिया

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About UHMWPE à¤à¤à¤

We are one of the trusted company engaged in offering a high quality range of ultra high molecular weight polyethylene (UHMWPE Component) to the clients.UHMWPE component is characterised by high levels of biocompatibility, hardness, and wear resistance. As a result, it is frequently utilised in joint arthroplasty as a bearing material with ceramic or metallic counter surfaces. A form of polyethylene with very long chains made up of very long strings of ethylene monomers is known as ultra-high molecular weight polyethylene (UHMWPE). The molecular weight of UHMWPE is the highest of any thermoplastic currently produced. By enhancing intermolecular interactions, the longer chain helps transfer weight to the polymer backbone more effectively. This produces a material that is extremely durable and has the highest impact strength of any thermoplastic.Superior Material Handling Solutions

Trust UHMWPE components for reliable material movement. Their high impact tolerance, smooth finish, and excellent wear resistance make them a preferred option in conveyor systems and industrial linings, lengthening equipment life and streamlining maintenance.

Customization for Every Application

We offer full flexibility in thickness (10 mm to 100 mm) and shape, customizing pieces precisely to your drawings or specifications. Whatever your industry needguides, strips, or rail partsour UHMWPE products are tailored for seamless integration.

FAQs of UHMWPE Component:

Q: How are UHMWPE components manufactured to meet specific size and shape requirements?

A: UHMWPE components are produced using compression molding, enabling customization of thickness (10 mm to 100 mm) and shape according to your specifications or drawings, ensuring they fit your unique application.Q: What makes UHMWPE suitable for material handling and conveyor systems?

A: UHMWPEs high impact strength, excellent wear resistance, and low water absorption make it ideal for use in material handling, conveyor systems, wear strips, linings, and guide rails, maximizing equipment longevity and efficiency.Q: When is it recommended to use custom-shaped UHMWPE parts?

A: Custom-shaped UHMWPE parts should be used when a standard component does not fit your machinery or system. They are essential for tailor-made solutions in complex assemblies or replacement applications as per specific design requirements.Q: Where do UHMWPE components typically serve in industrial environments?

A: UHMWPE components are commonly used in industries like food processing, packaging, mining, and bulk material handlingspecifically integrated as conveyor guides, wear strips, rail linings, and protective barriers.Q: What is the process for ordering UHMWPE components in custom colors or finishes?

A: Simply provide your color preference (white, black, green, or custom) and surface finish requirements, along with detailed drawings. Our manufacturing team will produce the components according to your specifications.Q: How do UHMWPEs material benefits enhance operational performance?

A: UHMWPEs smooth surface minimizes friction, its exceptional wear resistance sustains heavy cycles, and low water absorption averts degradation, all supporting longer operational life and reduced maintenance costs.Q: What are the usage benefits of UHMWPE compared to other plastics?

A: Compared to other plastics, UHMWPE offers outstanding machinability and high impact strength, ensuring reliable performance in demanding environments where both durability and ease of fabrication are required.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in UHMWPE Products Category

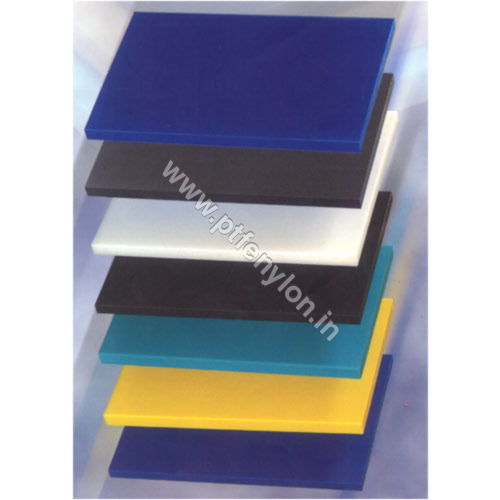

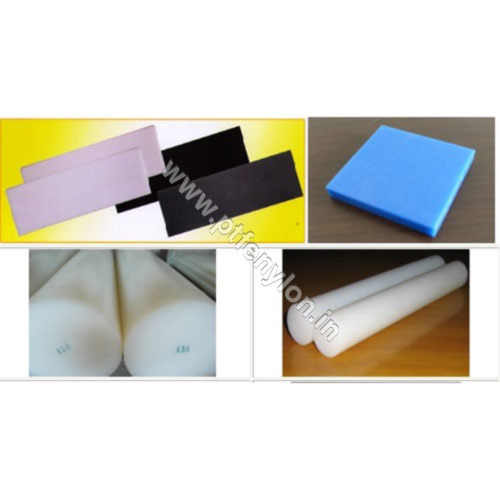

UHMWPE रंगीन शीट

न्यूनतम आदेश मात्रा : 10

प्लास्टिक मोल्डिंग प्रकार : Extruding

मूल्य या मूल्य सीमा : आईएनआर

शेप : Sheet

स्ट्रेंथ : High Impact Resistance

माप की इकाई : टुकड़ा/टुकड़े

UHMWPE रॉड्स

न्यूनतम आदेश मात्रा : 10

प्लास्टिक मोल्डिंग प्रकार : Extruding

मूल्य या मूल्य सीमा : आईएनआर

शेप : Round Rod

स्ट्रेंथ : High impact strength

माप की इकाई : टुकड़ा/टुकड़े

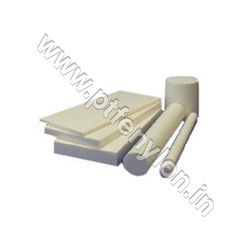

UHMWPE शीट

न्यूनतम आदेश मात्रा : 1

प्लास्टिक मोल्डिंग प्रकार : Extruding

मूल्य या मूल्य सीमा : आईएनआर

शेप : Rectangular

स्ट्रेंथ : High impact strength

माप की इकाई : टुकड़ा/टुकड़े

UHMWPE उत्पाद

न्यूनतम आदेश मात्रा : 10

प्लास्टिक मोल्डिंग प्रकार : ,

मूल्य या मूल्य सीमा : आईएनआर

शेप : Rectangular/Custom

स्ट्रेंथ : High

माप की इकाई : टुकड़ा/टुकड़े

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें