UHMWPE शà¥à¤

UHMWPE शà¥à¤ Specification

- प्रॉडक्ट टाइप

- Plastic Sheet

- प्लास्टिक का प्रकार

- प्लास्टिक मोल्डिंग प्रकार

- मोटाई

- 6 mm

- घनत्व

- ग्राम प्रति घन सेंटीमीटर (g/cm3)

- स्ट्रेंथ

- High impact strength

- शेप

- Rectangular

UHMWPE शà¥à¤ Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- एफओबी पोर्ट

- Mumbai

- भुगतान की शर्तें

- चेक, वेस्टर्न यूनियन, कैश एडवांस (CA)

- आपूर्ति की क्षमता

- प्रति सप्ताह

- डिलीवरी का समय

- हफ़्ता

- मुख्य निर्यात बाजार

- एशिया

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

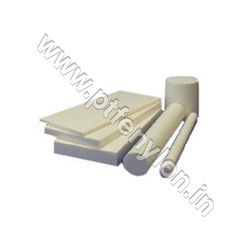

About UHMWPE शà¥à¤

From last many years, we are serving in the industry as one of the prominent manufacturers and suppliers of the UHMWPE Sheet. Our exceptional array of sheets is precisely manufactured as per the predefined international quality standards. Highly effective in performance, the range of bearings are used to pack the plastic films and bags. We offer our UHMWPE Sheet at highly economical prices with prompt deliveries.

Features:

- Superior quality

- Precise dimensions

- Require low maintenance

Exceptional Durability and Versatility

The UHMWPE sheet stands out for its high impact strength, excellent wear resistance, and negligible water absorption. Its impressive chemical resistance makes it suitable for harsh industrial environments, while the food-grade certification broadens its applicability to food processing and handling equipment. With a smooth finish and robust physical properties, its ideal for diverse uses.

Wide-Ranging Industrial Applications

Thanks to its low coefficient of friction (0.12 to 0.16), UHMWPE sheets function perfectly as conveyor guides, wear strips, liners, and chute sections. The material glides smoothly, minimizing operational downtime and maintenance costs. Manufacturers, exporters, and suppliers in India trust this product for its long-lasting utility and reliability in both mechanical and food industry equipment.

FAQs of UHMWPE Sheet:

Q: How is the UHMWPE sheet manufactured?

A: UHMWPE sheets are produced using the extrusion process, ensuring consistent thickness, a smooth surface finish, and superior mechanical properties. This method allows for the materials high density and homogenous structure, resulting in outstanding strength and durability.Q: What makes UHMWPE sheets suitable for food processing applications?

A: These sheets are food grade, meaning they comply with safety standards for direct contact with food. Their low water absorption and resistance to most chemicals further ensure hygienic and contamination-free operation in food handling and processing equipment.Q: When is it beneficial to use UHMWPE sheets in industrial settings?

A: UHMWPE sheets are beneficial whenever components require high wear resistance, low friction, or exposure to corrosive substances. They are commonly used for conveyor guides, liners, chutes, and other machinery parts that endure frequent mechanical stress or require long-lasting performance.Q: Where can UHMWPE sheets be applied beyond conveyor systems?

A: Aside from conveyor guides, these sheets are ideal for liners, chutes, wear strips, and machinery parts across industries such as mining, packaging, agricultural equipment, chemical processing, and food production, wherever high durability and chemical resistance are essential.Q: What are the main benefits of choosing UHMWPE sheets over other plastics?

A: UHMWPE sheets excel in wear resistance, tensile strength (25 MPa), and flexural modulus (~700 MPa), providing longevity and reducing maintenance costs. Their low coefficient of friction ensures efficient movement of parts, and high impact strength offers enhanced protection against damage and deformation.Q: How does the sheets chemical resistance benefit industrial operations?

A: The sheets high resistance to most acids and alkalis protects equipment from corrosive substances, extending life expectancy and reducing shutdowns for cleaning or replacement. This is especially advantageous in chemical plants, laboratories, and food processing facilities.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in UHMWPE Products Category

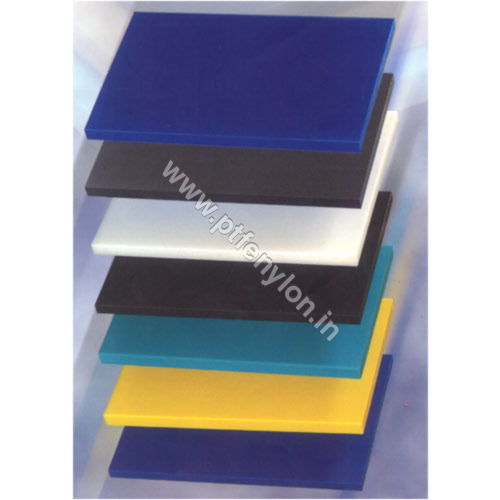

UHMWPE रंगीन शीट

स्ट्रेंथ : High Impact Resistance

न्यूनतम आदेश मात्रा : 10

माप की इकाई : टुकड़ा/टुकड़े

प्लास्टिक मोल्डिंग प्रकार : Extruding

शेप : Sheet

प्लास्टिक का प्रकार : ,

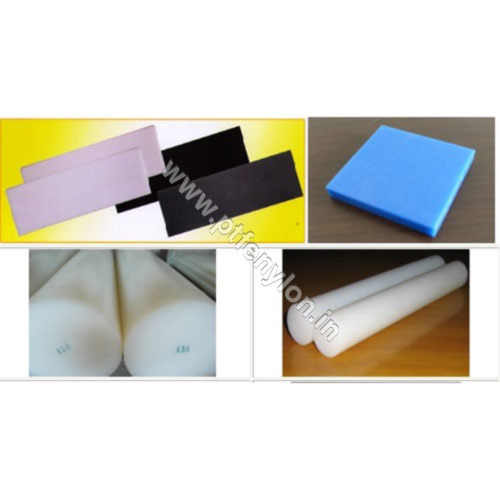

UHMWPE रॉड्स

स्ट्रेंथ : High impact strength

न्यूनतम आदेश मात्रा : 10

माप की इकाई : टुकड़ा/टुकड़े

प्लास्टिक मोल्डिंग प्रकार : Extruding

शेप : Round Rod

प्लास्टिक का प्रकार : ,

UHMWPE उत्पाद

स्ट्रेंथ : High

न्यूनतम आदेश मात्रा : 10

माप की इकाई : टुकड़ा/टुकड़े

प्लास्टिक मोल्डिंग प्रकार : ,

शेप : Rectangular/Custom

प्लास्टिक का प्रकार : ,

UHMWPE घटक

स्ट्रेंथ : High Impact Strength

न्यूनतम आदेश मात्रा : 1

माप की इकाई : टुकड़ा/टुकड़े

प्लास्टिक मोल्डिंग प्रकार : ,

शेप : Custom Shape (as per drawing or requirement)

प्लास्टिक का प्रकार : ,

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें